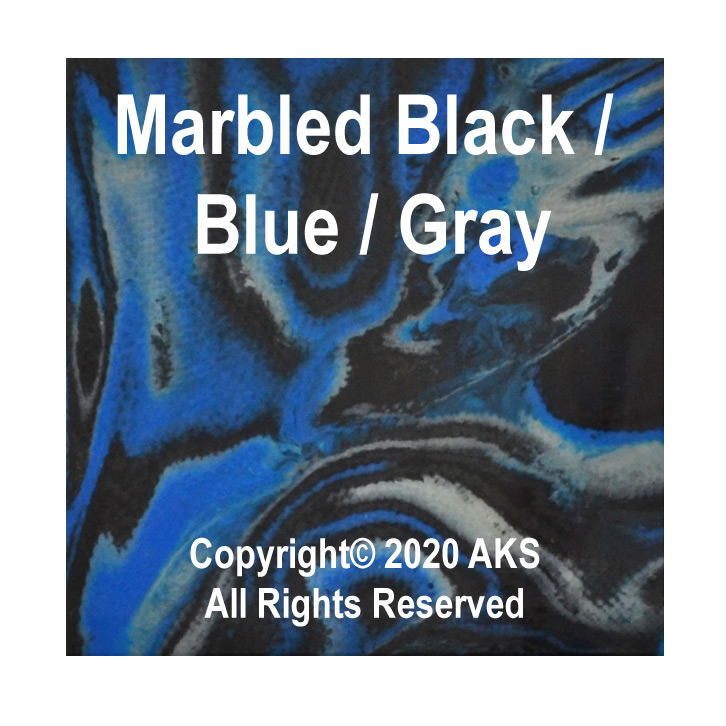

Marbled Black / Blue / Gray G10

| Description | Thick | Len | Wid | Price | Qty | Stock |

|---|

Marbled Black / Blue / Gray G10 – Scale |

.370 in | 11.6 in | 2.0 in | $79.30 |

-

+

|

GSMBLG-0370-116020 | 2 | |||

Marbled Black / Blue / Gray G10 – Scale |

.370 in | 11.6 in | 2.7 in | $100.80 |

-

+

|

GSMBLG-0370-116027 | 2 | |||

Marbled Black / Blue / Gray G10 – Scale |

.370 in | 11.6 in | 2.9 in | $108.30 |

-

+

|

GSMBLG-0370-116029 | 1 |

Marbled Black / Blue / Gray G10 Sheet Info & FAQ

Marbled Black / Blue / Gray G10 is an aesthetic material that looks great. It is a combination of black, royal blue and gray G10 that is manipulated during the manufacturing process to show a random pattern. This color combination has a pleasing, high end look that is not obnoxious.

Pros: It has a random appearance that is almost impossible to repeat. Every piece we received looks different.

Cons: Because of how marbled G10 is made, don't be surprised if you find a void. Marbled G10 does not have the strength properties of standard layered G10. Do not use marbled G10 for structural or applications where strength is needed. Some pieces may have a slight curve.

Working Tips:

Cut, machine and sand marbled G10 like regular G10. It looks good when sanded smooth and buffed. An alternate finish is a sanding smooth until all scratches are removed and then a very light bead blast. This bead blast finish does an excellent job of showing the figure in the G10. Voids can be filled with a mixture of dark G10 dust and epoxy or cyanoacrylate (super glue).

General

G10 is a composite of epoxy and glass mat bonded together under high pressure and heat. Multiple layers are built up until the desired thickness is achieved. The G10 and phenolic sheet we sell is made in the United States. Our manufacturers have been making excellent quality composites for decades. We have been to one of their factories multiple times and have watched G10 being made.

Working Tips

The high glass content of G10 does make it more challenging to machine than phenolic composites. The easiest way to cut G10 is to use a wet diamond saw. We are frequently asked how to texture G10 handles. We recommend finishing the handle, masking off the blade and then bead blasting the handle with coarse grit. You decide how coarse you like. After bead blasting, spray the handle with WD40 and then throughly wash the handle with Dawn dishwashing soap. When done properly, the finished handle has good grip and the color of the G10 is evident.

Raw Material Concerns

G10 is not a miracle material. Some people incorrectly assume it is flat. We measure every piece of G10 we sell. Every piece of G10 has runout. We round the measurement down so you will never receive less than what we have listed on the website.

The G10 we sell is a raw material, not a finished product. It has minor surface scratches, dings, scrapes and other imperfections. It must be machined and/or sanded before it is in a finished state.

Quality Problems

We frequently hear stories from customers about G10 failures. The one common point is the bad G10 was not from AKS. The most common failure is cracking and/or brittleness. This is not a problem with high quality G10 but is a common problem with offshore G10.

The reason poor quality G10 easily cracks or is brittle is because the manufacturer reduced the number of glass mat layers and increased the amount of epoxy. In terms of cost, epoxy is cheap and glass mat is expensive.

There are suppliers here in the U.S. who are selling G10 made offshore, and I’m not just referring to Alibaba. Do your homework and ask suppliers where their G10 is made. Test the material yourself by breaking some pieces.

Summary

G10 is an excellent handle material as long as you are aware of, and work within, its limitations. You owe it to yourself and your customers to use the best materials possible.

Bowie Blocks™

At a show in April 2004 we introduced the Bowie Block™. The response was great and we've stocked the blocks since that time.

A Bowie Block™ is a block of handle material with a unique shape. Rather than being a rectangular block, the material is cut at an angle on one side. The shape allows knifemakers to make a handle that drops at the back. The shape of the block minimizes waste and cost.

The width column has two measurements. The first measurement is the narrow end of the block. The second measurement is the wide end of the block.

Marbled Black / Blue / Gray G10 Sheet, Scales, Liners and Blocks